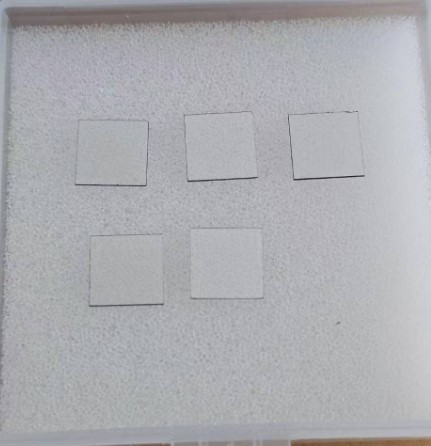

Ultra thin Sub 100 μm Single Crystalline Diamond Film Window

Laser Stealth Dicing for Ultrathin Single-Crystal Diamond Separation

Background and Challenge

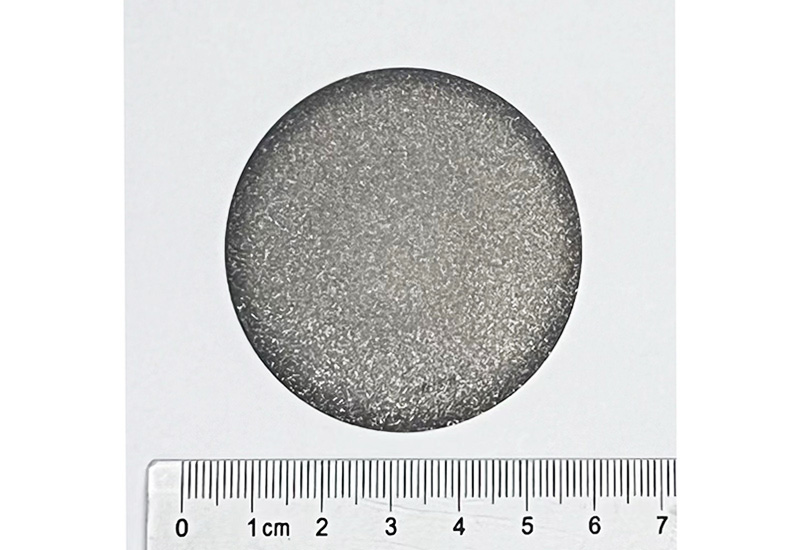

Single-crystal diamond is prized for its exceptional thermal conductivity, ultra-wide bandgap, high breakdown field, excellent carrier mobility, and wide-spectrum transparency—making it ideal for advanced electronics, optics, and quantum technologies. However, machining it into <100 μm ultrathin wafers is difficult, costly, and inefficient with conventional methods such as wire sawing, laser ablation, or plasma etching, which cause high material loss, slow throughput, or surface damage.

Laser Stealth Dicing Principle

Laser stealth dicing enables internal, contactless separation of diamond without surface damage:

Penetration and Focus: Ultrafast lasers (picosecond/femtosecond) at sub-bandgap wavelengths pass through the diamond and are focused precisely at a targeted internal depth.

Localized Modification: Nonlinear absorption induces a controlled phase change (from sp³ to sp² carbon) within a thin internal layer.

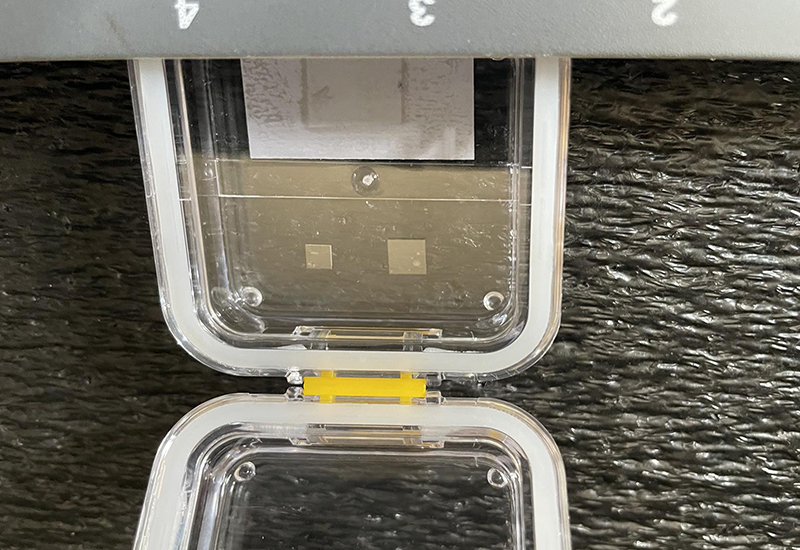

Layer Formation and Cleavage: Scanning the laser creates a continuous weakened plane. A small mechanical or thermal force then cleanly separates the wafer along this layer.

Key Advantages

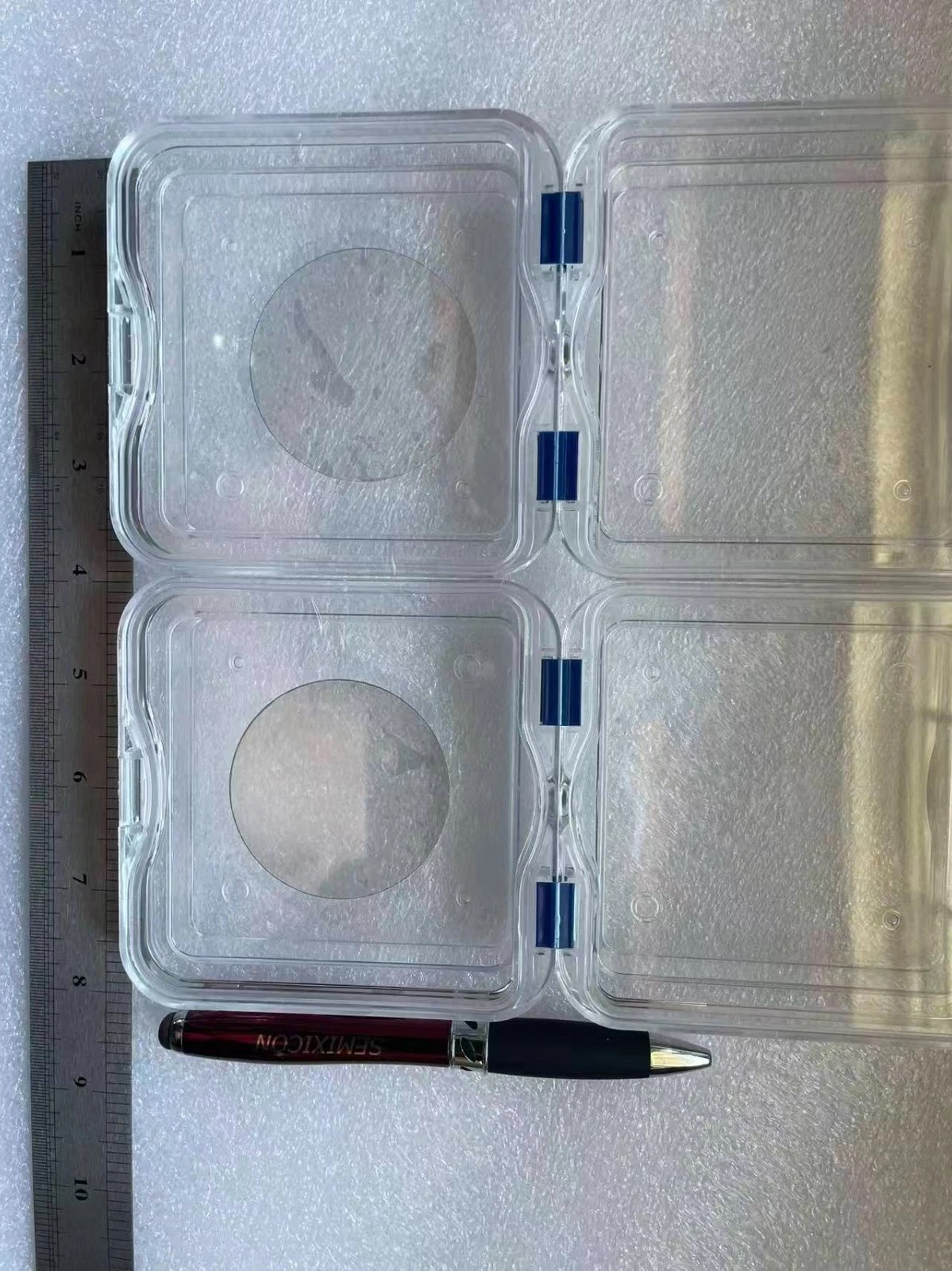

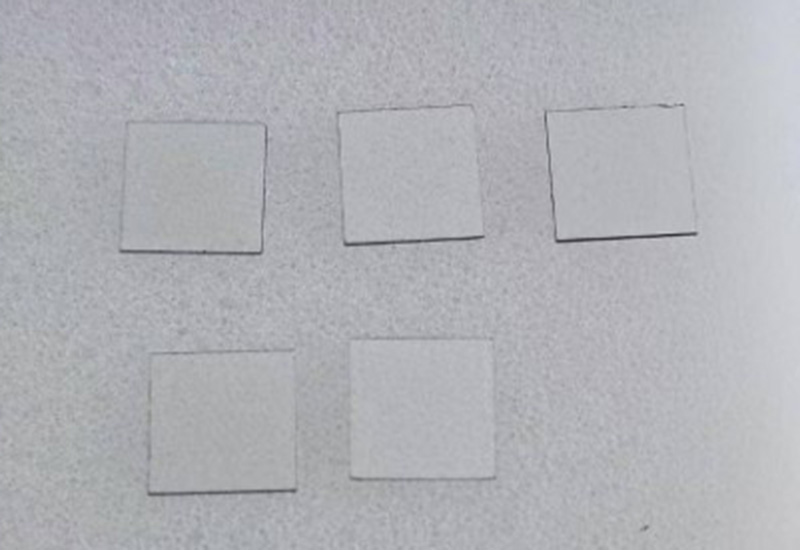

Ultrathin Capability: Consistently produces <100 μm thick wafers.

Minimal Material Loss: <100 μm, even for larger wafers (1–6 inch), greatly improving yield.

High Throughput: <30 minutes per 1-inch wafer—orders of magnitude faster than traditional techniques.

Superior Quality: Contactless and low-thermal process preserves crystal integrity, reducing post-processing.

Scalable and Automatable: Compatible with industry wafer sizes and high-volume manufacturing.

Application Potential

High-Power Electronics: As heat spreaders directly integrated into chips (RF, CPUs, lasers ), improving thermal performance and reliability.

Quantum Sensors: Enables near-surface NV centers for enhanced sensitivity and resolution.

Advanced Optical Windows: Ideal for extreme environments (e.g., lasers, oil/gas, aerospace) due to hardness, transparency, and durability.

Emerging Fields: Supports development in SAW filters, biosensors, and protective coatings.

Laser stealth dicing provides a fast, precise, and low-loss solution to produce ultrathin single-crystal diamond, removing a key barrier to its adoption in high-end electronics, quantum tech, and optics.

SEMIXICON DIASEMI

Fremont CA

7/4/2025